What is the first thing to check if a solenoid valve fails to open?

Understanding Solenoid Valves

Basics of Solenoid Valves

Solenoid valves are essential components in various systems, including crop spraying equipment. These devices convert electrical energy into mechanical energy, allowing you to control the flow of fluids within your machinery efficiently. When an electrical current flows through the wire coil of the solenoid, it creates a magnetic field, which triggers a mechanical response (Solenoid Valves).

Solenoid valves come in different types, but they all serve the same fundamental purpose: to regulate the flow of fluids. They are particularly useful in agricultural applications, where precise control over the distribution of water, fertilizers, and pesticides is crucial. Understanding the basics of solenoid valves will help you maintain and troubleshoot your crop spraying equipment effectively.

Operating Principles

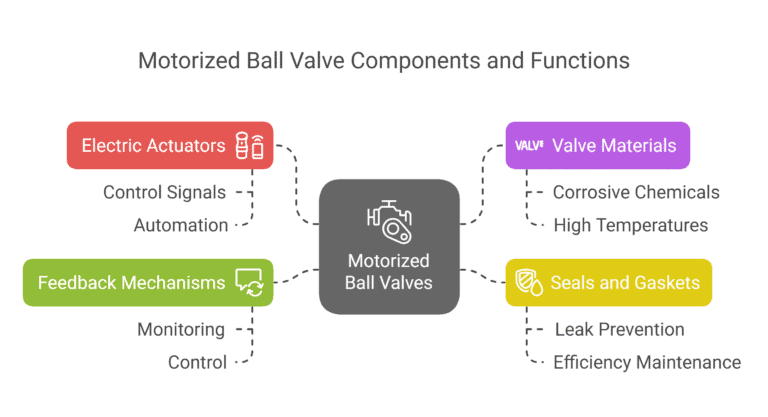

The operating principles of solenoid valves are straightforward yet powerful. The key components include a coil of wire, a plunger or shaft, and a valve seat. Here’s how they work:

- Electrical Activation: When you apply an electrical current to the solenoid coil, it generates a magnetic field. The strength of this magnetic field depends on the voltage applied and the number of turns in the coil.

- Magnetic Response: The magnetic field created by the current flow causes the plunger or shaft to move. This movement can either open or close the valve, depending on the design of the solenoid valve. Direct-acting valves use the magnetic field to move the shaft directly, while pilot-operated valves use the fluid pressure to assist in opening the valve.

- Fluid Control: The movement of the plunger or shaft controls the flow of the fluid. In crop spraying systems, this means you can precisely regulate the amount of water, fertilizer, or pesticide being distributed to your crops. This precise control is essential for ensuring even coverage and avoiding waste.

For a clearer understanding, here’s a simple table summarizing the key factors that influence the operation of solenoid valves:

| Factor | Impact |

|---|---|

| Voltage | Determines the strength of the magnetic field, affecting the plunger’s movement. |

| Number of Turns in the Coil | Affects both the voltage and current, influencing the efficiency of the valve. |

| Type of Valve | Direct-acting valves require full power, while pilot-operated valves use fluid pressure to assist in operation. |

To delve deeper into the specifics of solenoid valves, including their types and applications, check out our detailed guide on solenoid valves. Understanding these basics and operating principles will equip you with the knowledge to maintain and troubleshoot your crop spraying systems effectively. For more on what triggers a solenoid valve, visit our article on what triggers a solenoid valve.

Factors Influencing Solenoid Valves

Understanding the factors that influence solenoid valves can help you better maintain and troubleshoot these essential components in your crop spraying equipment. Key factors include voltage, magnetic field strength, and the number of turns in the coil.

Voltage and Magnetic Field

The voltage applied to a solenoid determines the strength of the magnetic field it produces. As the voltage increases, the current flowing through the solenoid also increases, resulting in a stronger magnetic field. This magnetic field is what triggers the solenoid valve to open or close.

| Voltage (V) | Magnetic Field Strength |

|---|---|

| 12 VDC | Moderate |

| 24 VDC | Strong |

| 110 VAC | Very Strong |

| 220 VAC | Extremely Strong |

It’s crucial to match the solenoid valve’s nominal actuation voltage with the power supply. Common voltages include 12 VDC, 24 VDC, 110 VAC, and 220 VAC. Undervoltage can result in the valve not opening, while overvoltage can lead to a faster “on” response time but may damage the coil permanently (Solenoid Uses). For more information on what triggers a solenoid valve, visit our article on what triggers a solenoid valve.

Number of Turns in the Coil

The number of turns in the solenoid coil also plays a significant role in its operation. The number of turns affects both the voltage and current in a linear relationship. As the number of turns increases, the voltage required to produce a certain current also increases (Physics Forums).

| Number of Turns | Required Voltage (V) | Current (A) |

|---|---|---|

| 100 | 12 | 1 |

| 200 | 24 | 1 |

| 400 | 48 | 1 |

Various factors, such as the material and size of the core, the wire’s resistance, and the type and strength of the power source, can impact the voltage and current in a solenoid (3-way plug valve). By understanding these relationships, you can better diagnose issues with your solenoid valves and ensure they operate efficiently.

For further details on how solenoid valves work and their applications in agricultural equipment, explore our article on solenoid valves.

Applications of Solenoid Valves

Solenoid valves are essential components in various systems, offering precise control over the flow of liquids and gases. In this section, we will delve into their applications in industrial machinery, automobiles, agricultural equipment, and systems.

Industrial Machinery and Automobiles

In industrial settings, solenoid valves are utilized to control machines, dose, mix, or restrict the flow of liquids or gases. For instance, in beverage factories, solenoid valves measure the exact amount of drink to be poured into bottles. Similarly, pneumatic solenoid valves regulate the passage of air in circuits, while liquid solenoid valves manage the flow of liquid mediums.

In the automotive industry, solenoid valves play a crucial role in regulating the flow of automotive fluids such as oil, anti-skid brake fluid, or fuel. Variable solenoid valves are often used for these functions. These valves ensure that your vehicle operates smoothly and efficiently.

Agricultural Equipment and Systems

For middle-aged farmers looking to improve their crop spraying, understanding the role of solenoid valves in agricultural equipment is vital. Most agricultural machinery, including irrigation devices like automatic sprinklers and motorized farm machines, relies on solenoid valves to control various systems (Starter Solenoid).

In crop spraying, solenoid valves help dose and mix pesticides, fertilizers, and other substances accurately. This ensures that your crops receive the right amount of treatment, enhancing yield and reducing waste. For more insights into solenoid valves in agriculture, visit our section on solenoid valves.

| Application | Function |

|---|---|

| Automatic Sprinklers | Control water flow |

| Motorized Farm Machines | Dose and mix substances |

| Crop Sprayers | Accurate application of pesticides and fertilizers |

Solenoid valves are also used in various other agricultural systems, including irrigation control and greenhouse automation. By understanding what triggers a solenoid valve, you can better maintain and troubleshoot your equipment. For detailed information, refer to our article on what triggers a solenoid valve?.

By integrating solenoid valves into your agricultural practices, you can achieve precise control over your farming processes, leading to improved efficiency and productivity.

Types of Solenoid Valves

When selecting the right solenoid valve for your crop spraying system, it’s essential to understand the different types available. This knowledge will help you make informed decisions and ensure the efficient operation of your equipment. Here, we explore the main categories: direct-acting vs. pilot-operated valves, and 2-way, 3-way, and 4-way valves.

Direct-Acting vs. Pilot-Operated

Direct-Acting Solenoid Valves

Direct-acting solenoid valves operate by using the magnetic force from the coil to directly push or pull a shaft, which opens or closes the valve seat. These valves require full power to operate and can be either normally open or normally closed depending on the application. They are known for their quick response time, reliability, and compact design.

| Feature | Direct-Acting Solenoid Valve |

|---|---|

| Operation | Uses magnetic force to directly actuate the valve |

| Power Requirement | Full power |

| Response Time | Fast |

| Design | Compact |

| Applications | Ideal for systems requiring quick response and reliability |

Pilot-Operated Solenoid Valves

Pilot-operated solenoid valves use the pressure of the fluid in the line to open the valve. This design allows for the use of a smaller coil and lower cost. However, these valves require sufficient pressure to operate effectively (3-way zone). They are suitable for applications where there is a consistent pressure differential and a need for high flow rates.

| Feature | Pilot-Operated Solenoid Valve |

|---|---|

| Operation | Utilizes fluid pressure to actuate the valve |

| Power Requirement | Lower power due to smaller coil |

| Response Time | Dependent on fluid pressure |

| Design | Larger than direct-acting |

| Applications | Ideal for high flow rates and systems with consistent pressure |

2-Way, 3-Way, and 4-Way Valves

2-Way Solenoid Valves

2-way solenoid valves are used in on/off applications that require quick response and higher flow. These valves have two ports, an inlet and an outlet, and can either be normally open or normally closed (3-way ball valve).

| Feature | 2-Way Valve |

|---|---|

| Ports | 2 (inlet and outlet) |

| Operation | On/Off |

| Applications | Quick response and high flow requirements |

3-Way Solenoid Valves

3-way solenoid valves have three port connections and two valve seats. One valve seal always remains open, and the other closed in the de-energized mode. When the coil is energized, the mode reverses. These valves are used in applications requiring the alternate pressurization and exhaust of a valve actuator.

| Feature | 3-Way Valve |

|---|---|

| Ports | 3 |

| Operation | Alternate pressurization and exhaust |

| Applications | Controlling valve actuators |

4-Way Solenoid Valves

4-way solenoid valves have four or more port connections and are typically used for controlling double-acting cylinders or actuators. These valves are versatile and can direct flow to multiple outlets, making them ideal for complex machinery and systems.

| Feature | 4-Way Valve |

|---|---|

| Ports | 4 or more |

| Operation | Controls double-acting cylinders or actuators |

| Applications | Complex machinery and systems |

Understanding the differences between these types of solenoid valves will help you determine what triggers a solenoid valve and choose the best one for your crop spraying needs. For more information on maintaining and troubleshooting your solenoid valves, check out our comprehensive guide on solenoid valves.