What is the difference between a solenoid and a solenoid valve?

Understanding Solenoid Valves

Basics of Solenoid Valves

A 2-way solenoid valve is a crucial component in various agricultural systems, including crop spraying equipment. Understanding its basics can help you make informed decisions about your farming operations.

A 2-way, normally closed, solenoid valve has two pipe connections: an inlet called the cavity port and an outlet called the body orifice port. When the valve is energized, the plunger opens, allowing media to flow through the valve from the cavity port and out the body orifice port. When the power is turned off, the orifice closes, and the flow through the valve stops.

In a normally closed solenoid valve, the resting position is off, impeding the flow of media. When electricity is sent through the coil of wire, an electromagnetic field is produced, moving the plunger and forcing the core to move upwards against the spring, opening the valve. When the electricity is shut off, the core moves back down to its original position, and the spring pushes the plunger back down to shut the valve, stopping the flow of gases or liquids (Electric Solenoid Valves).

| Feature | Description |

|---|---|

| Pipe Connections | Inlet (cavity port) and outlet (body orifice port) |

| Operation | Energized to open, de-energized to close |

| Resting Position | Normally closed (off) |

| Media Type | Gases or liquids |

Components of a Solenoid Valve

A 2-way solenoid valve consists of several key components that work together to control the flow of media. These components include:

- Housing: The body of the valve, which can be made from metal or plastic, providing structural integrity and protection for the internal parts.

- Valve Spool: A cylindrical plunger attached to an armature that moves inside the chamber to open and close the valve.

- Coil: An electromagnetic coil of wire that generates a magnetic field when electricity passes through it, causing the plunger to move (Valves Actuator).

| Component | Function |

|---|---|

| Housing | Protects internal parts and provides structural integrity |

| Valve Spool | Moves to open and close the valve |

| Coil | Generates a magnetic field to move the plunger |

Understanding these components and their functions can help you select the right 2-way solenoid valve for your agricultural needs. For more information on selecting the right valve, visit our section on considerations for valve selection.

Selecting the Right Solenoid Valve

Choosing the right 2 way solenoid valve for your agricultural needs is crucial for ensuring efficient and reliable operation. This section covers key considerations to help you make an informed decision.

Considerations for Valve Selection

When selecting a 2 way solenoid valve, several factors need to be taken into account:

- System’s Pressurized Fluid: Determine whether the fluid is gas or liquid. The type of fluid affects the valve’s material and design. For example, a valve designed for gas may not be suitable for liquid applications.

- Pressure Range: Identify the minimum and maximum system pressure. The valve must be able to withstand these pressures to ensure a long cycle life.

- Chemical Properties: Consider the chemical properties of the fluid. Incompatible materials can lead to valve degradation and failure. Ensure the valve material is chemically compatible with the fluid.

- Temperature: High or low temperatures can affect the valve’s performance. Choose a valve that can operate within the temperature range of your system.

- Flow Capacity: Properly size the valve to handle the required flow rate. Use the flow coefficient (Cv, Kv) provided by manufacturers to compare and select the appropriate valve.

| Consideration | Importance |

|---|---|

| System’s Pressurized Fluid | Ensures compatibility and efficiency |

| Pressure Range | Guarantees valve durability |

| Chemical Properties | Prevents material degradation |

| Temperature | Maintains performance |

| Flow Capacity | Avoids system performance issues |

Compatibility with System Requirements

Ensuring the solenoid valve is compatible with your system’s requirements is vital:

- Operating Conditions: Consider factors beyond ideal scenarios, such as pressure fluctuations, quality of the media, and extreme temperatures. The valve should be able to handle these conditions without compromising performance.

- Work Environment: Take into account the environment where the valve will be used. Dust, moisture, and other environmental factors can affect the valve’s operation.

- Cycle Rates and Energized Times: High cycle rates and prolonged energized times can lead to wear and tear. Select a valve designed to handle the expected usage patterns.

- Leakage Potential: Anticipate potential leakage and choose a valve with a low leakage rate to minimize maintenance and downtime.

For more detailed guidance on selecting the right solenoid valve, consider consulting with a reliable valve manufacturing partner. They can provide expert advice tailored to your specific application.

To learn more about the differences between solenoid valves, visit our article on what is the difference between a 2 way and 3 way solenoid valve. For a deeper understanding of how these valves work, check out how does a 2 way control valve work?.

Applications of 2-Way Solenoid Valves

Industrial Uses

2-way solenoid valves are essential components in various industrial applications due to their ability to control the flow of fluids efficiently. They are widely used in the following sectors:

- Automotive Industry: In automotive systems, 2-way solenoid valves regulate the flow of fuel and air into the engine, ensuring optimal performance. They also control hydraulic fluid pressure in industrial machinery, enhancing operational efficiency.

- Chemical and Food Processing: These valves maintain desired temperatures and flow rates, ensuring that process fluids meet specific standards. This regulation is critical for both safety and quality control.

- Power Generation: In power plants, 2-way solenoid valves help manage the flow of steam and water, contributing to efficient energy production and system stability.

- Water Treatment: These valves are used in water treatment plants to control the flow of water and chemicals, ensuring clean and safe water supply.

- Marine Applications: In marine systems, 2-way solenoid valves are employed to manage the flow of fuel, water, and other fluids, ensuring the smooth operation of marine vessels.

| Industry | Application |

|---|---|

| Automotive | Regulating fuel and air flow, hydraulic control |

| Chemical | Maintaining process fluid standards |

| Food Processing | Ensuring safety and quality control |

| Power Generation | Managing flow of steam and water |

| Water Treatment | Controlling water and chemical flow |

| Marine | Managing fuel and fluid flow |

Agricultural Implementations

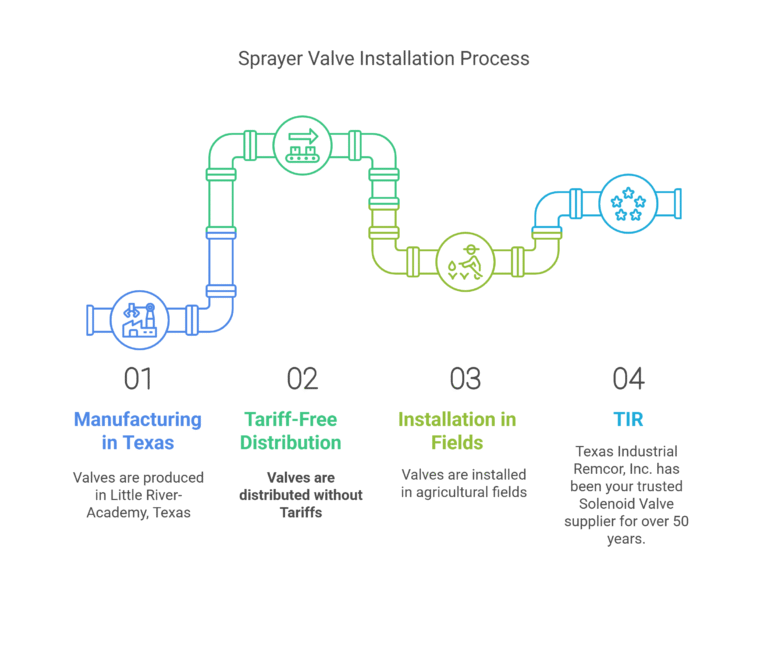

In agriculture, 2-way solenoid valves play a pivotal role in various irrigation and crop spraying systems. Their ability to provide precise control over fluid flow makes them indispensable for modern farming practices.

- Irrigation Systems: 2-way solenoid valves are commonly used in automated irrigation systems to control the flow of water to different zones. This ensures efficient watering of crops, lawns, gardens, and other outdoor plants. These valves can be programmed to open and close at specific times, conserving water and optimizing irrigation (Electric Solenoid Valves).

- Crop Spraying: In crop spraying systems, 2-way solenoid valves regulate the distribution of pesticides, herbicides, and fertilizers. This ensures that the right amount of chemicals is applied uniformly, enhancing crop yield and minimizing waste.

- Greenhouse Climate Control: These valves are also used in greenhouse environments to control water and nutrient delivery systems. By automating these processes, farmers can create optimal growing conditions for their crops.

- Livestock Watering Systems: In livestock farming, 2-way solenoid valves control water flow to drinking stations, ensuring that animals have access to fresh water at all times.

For more information on how 2-way solenoid valves can benefit your agricultural practices, check out our detailed guide on 2 way solenoid valve.

| Application | Benefit |

|---|---|

| Irrigation Systems | Efficient water distribution |

| Crop Spraying | Uniform application of chemicals |

| Greenhouse Climate Control | Optimal growing conditions for crops |

| Livestock Watering Systems | Consistent access to fresh water for animals |

By understanding the various applications of 2-way solenoid valves, you can select the right valve for your specific needs. Whether it’s for industrial use or agricultural implementation, these valves provide reliable and efficient control over fluid flow, contributing to the overall success of your operations. For further insights on valve selection, visit our article on what is the difference between a 2 way and 3 way solenoid valve.

Maintenance and Troubleshooting

To ensure optimal performance of your 2 way solenoid valve in agricultural applications, regular maintenance and timely troubleshooting are essential. Here are some tips and common issues to help you keep your valve in top condition.

Tips for Maintenance

- Regular Cleaning: Periodically clean the valve to prevent debris buildup, which can obstruct the flow and decrease efficiency. Use a soft brush and appropriate cleaning solutions to remove any dirt or sediment.

- Inspect Seals and Gaskets: Check the seals and gaskets for any signs of wear or damage. Replace them if necessary to maintain a tight seal and prevent leaks.

- Lubricate Moving Parts: Apply a suitable lubricant to the moving parts of the valve to reduce friction and wear.

- Check Electrical Connections: Ensure that all electrical connections are secure and free from corrosion. Loose or corroded connections can lead to malfunction.

- Monitor Performance: Regularly observe the valve’s performance and listen for any unusual noises that might indicate a problem.

Common Issues and Solutions

Knowing the common issues that can arise with 2 way solenoid valves and their solutions can save you time and money.

| Issue | Cause | Solution |

|---|---|---|

| Valve Fails to Open or Close | Electrical malfunction or debris | Check electrical connections and clean the valve |

| Leakage | Worn-out seals or gaskets | Inspect and replace seals or gaskets |

| Reduced Flow Rate | Obstruction in the valve | Clean the valve and ensure it’s free from debris |

| Overheating | Excessive use or improper voltage | Ensure correct voltage and allow the valve to cool down between uses |

| Corrosion | Exposure to harsh chemicals or moisture | Use corrosion-resistant materials and keep the valve dry |

For more detailed guidance on maintaining your solenoid valve, consider consulting your valve manufacturer or exploring resources on how does a 2 way control valve work.

By following these maintenance tips and addressing common issues promptly, you can extend the lifespan of your 2 way solenoid valve and ensure it operates efficiently. For further assistance, consider reaching out to a reliable valve manufacturer for expert advice.