What is a 2 way solenoid valve?

Understanding Solenoid Valves

Solenoid valves are essential components in various agricultural applications, especially in crop spraying systems. They offer precise control over fluid flow, ensuring efficient and accurate operations.

Basics of Solenoid Valve Operation

A solenoid valve is an electromechanical device used to control the flow of fluids or gases. It consists of a solenoid (coil), a plunger, and a valve body. When an electric current passes through the solenoid, it creates a magnetic field that moves the plunger. This movement either opens or closes the valve, regulating the flow of the medium through the system.

For example, a 2-way solenoid valve, which is commonly used in crop spraying, has two positions: open and closed. When the valve is energized, the plunger lifts, allowing the fluid to flow from the inlet port to the outlet port. When the power is turned off, the plunger returns to its original position, stopping the flow. You can read more about how a 2-way control valve works on our dedicated page: how does a 2 way control valve work?.

Types of Solenoid Valves

Solenoid valves come in various types, each designed for specific applications. Here are some common types you might encounter:

- 2-Way Solenoid Valve: This valve has two ports (inlet and outlet) and two positions (open and closed). It is typically a normally closed (NC) valve, meaning it stays closed when not powered and opens when energized. It is ideal for simple on/off control of fluids. Learn more about this type by visiting our page on 2 way solenoid valve. Valve TypePortsPositionsDiagram2-Way (NC)Inlet, OutletOpen, Closed

- 5/2-Way Solenoid Valve: This valve has five ports and two states, allowing it to switch between two different states. It is used primarily for controlling pneumatic actuators or cylinders.

- 4/2-Way Solenoid Valve: This valve has four ports and two positions, commonly used for double-acting cylinders. It shares a similar function with the 5/2-way valve but has different port arrangements.Valve Type Ports Positions Usage 5/2-Way Five Two Pneumatic Control 4/2-Way Four Two Double-Acting Cylinders

Each type of solenoid valve offers unique advantages depending on the application. For a deeper understanding of the differences between 2-way and 3-way valves, visit our guide: what is the difference between a 2 way and 3 way solenoid valve.

By understanding the basics of solenoid valve operation and the various types available, you can make informed decisions that enhance the efficiency and effectiveness of your agricultural practices.

Applications in Agriculture

Importance in Crop Spraying

The 2 way solenoid valve plays a vital role in crop spraying applications. In modern agriculture, precision and efficiency are crucial for maximizing crop yield. A 2 way solenoid valve helps achieve these goals by controlling the flow of liquids, such as pesticides and fertilizers, with pinpoint accuracy.

In crop spraying systems, the solenoid valve operates by opening and closing to regulate the spray pattern and coverage. This ensures that your crops receive the exact amount of nutrients or protection they need, reducing waste and improving overall crop health. It’s essential for minimizing the environmental impact of chemical usage and ensuring compliance with agricultural regulations.

Efficiency in Farming Operations

Efficiency is a key concern in farming operations, and the 2 way solenoid valve significantly contributes to this aspect. By automating the flow control, these valves reduce the need for manual intervention, allowing you to focus on other critical aspects of farming.

The quick response time of solenoid valves ensures that the spraying system operates seamlessly, providing consistent and uniform application across your fields. This consistency helps prevent over- or under-application, which can lead to crop damage or reduced effectiveness of the applied chemicals.

Additionally, solenoid valves are highly durable and designed to withstand harsh agricultural environments. This reliability translates to reduced downtime and maintenance, further enhancing the efficiency of your farming operations.

For more information on how a 2 way control valve works, visit our article on how does a 2 way control valve work. To explore the different options available, check out the comparison between 2 way and 3 way solenoid valves.

By incorporating a 2 way solenoid valve into your crop spraying system, you can achieve precise control, improved efficiency, and better crop health, ultimately leading to higher yields and more sustainable farming practices.

Key Features to Consider

When selecting a 2 way solenoid valve for your agricultural needs, it’s crucial to consider several key features. These features ensure that the valve operates efficiently and reliably in your crop spraying and farming operations.

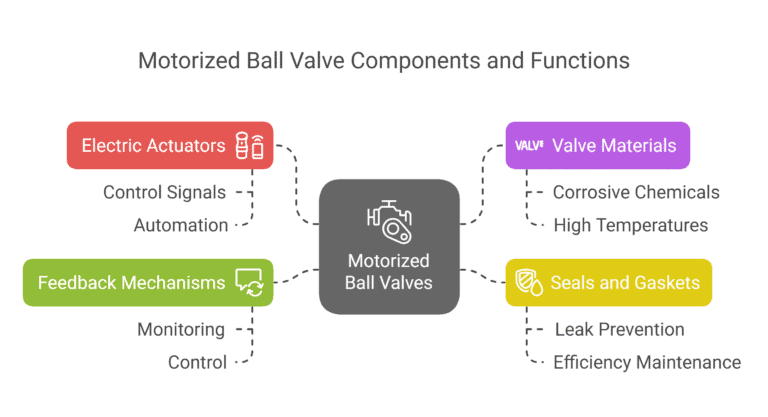

Valve Design and Functionality

The design and functionality of a 2 way solenoid valve are fundamental to its operation. A 2-way, normally closed solenoid valve has two pipe connections: an inlet called the cavity port and an outlet called the body orifice port (Solenoid Solutions). When the valve is energized, the plunger opens, allowing media to flow through the valve from the cavity port and out the body orifice port. When the power is turned off, the orifice closes, stopping the flow.

Key Points:

- Inlet and Outlet Ports: Ensure the valve has the correct connections for your system.

- Flow Control: The valve should provide precise control over the flow of liquids or gases.

- Operation Mechanism: Understand whether the valve is normally open or normally closed and choose based on your specific needs.

Material Selection and Compatibility

Material selection is critical for ensuring the solenoid valve’s durability and compatibility with the media being used. Solenoid valves are used for neutral liquids and gases such as oils, lubricants, fuels, water, air, or steam. The materials should be compatible with the medium to prevent corrosion, wear, and other forms of damage.

| Medium | Compatible Materials |

|---|---|

| Water | Brass, Stainless Steel |

| Oils and Lubricants | Brass, Stainless Steel, NBR Seals |

| Fuels | Brass, Stainless Steel, FKM Seals |

| Air | Brass, Stainless Steel, EPDM Seals |

| Steam | Stainless Steel, PTFE Seals |

- Brass: Good for water, oils, and fuels.

- Stainless Steel: Suitable for a wide range of media, including corrosive substances.

- Seals: Ensure the seals are compatible with the media (e.g., NBR for oils, FKM for fuels).

Ensuring the right material compatibility will extend the life of your valve and maintain its performance. For more detailed guidelines on selecting the right materials, visit our article on how does a 2 way control valve work.

By considering these key features, you can select the best 2 way solenoid valve for your agricultural applications, ensuring efficiency and reliability in your farming operations. For more information on the differences between valve types, check out what is the difference between a 2 way and 3 way solenoid valve.

Maintenance and Safety Tips

For optimal performance and longevity of your 2 way solenoid valve in agricultural applications, proper maintenance and adherence to safety guidelines are essential. Here are some crucial tips:

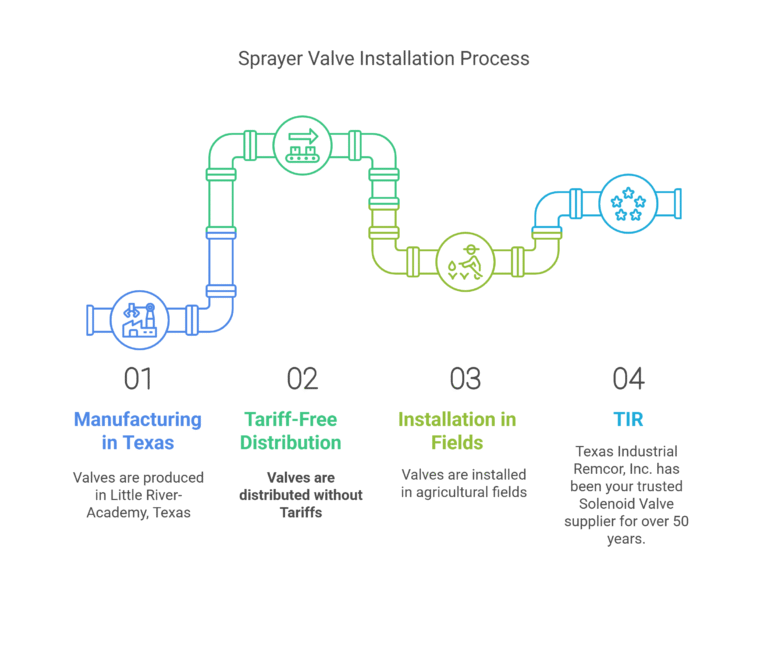

Proper Installation Procedures

Ensuring the correct installation of your solenoid valve is key to its efficient operation. Follow these steps for proper installation:

- Check Compatibility: Verify that the valve materials are compatible with the media (e.g., oils, lubricants, fuels, water, air, steam) being used.

- Positioning: Install the valve in the correct orientation, typically indicated by arrows on the valve body showing the direction of flow.

- Pipe Connections: Securely connect the inlet (cavity port) and outlet (body orifice port) pipes to avoid leaks. Apply appropriate thread sealant to ensure a tight seal.

- Electrical Connections: Ensure that the power supply matches the valve specifications. Properly connect the wires following the manufacturer’s instructions.

- Testing: After installation, test the valve manually if it has an override mechanism, to ensure it operates correctly before full deployment.

Safety Guidelines for Usage

To ensure safe and effective use of your 2 way solenoid valve, adhere to the following safety guidelines:

- Regular Inspections: Frequently inspect the valve for wear and tear, leaks, or any signs of damage. Address any issues promptly to prevent malfunctions.

- Temperature Control: Monitor the operating temperature to ensure it remains within the specified range for your valve. Excessive heat can damage the internal components.

- Pressure Limits: Ensure that the operating pressure does not exceed the valve’s rated capacity. Over-pressurization can lead to valve failure.

- Cleanliness: Keep the valve and its surrounding area clean to prevent contamination and blockages. Regularly flush the system to remove any debris.

- Emergency Shutdown: Be familiar with the emergency shutdown procedures in case of a valve malfunction. Ensure that the power supply can be quickly and safely disconnected.

| Maintenance Task | Frequency | Notes |

|---|---|---|

| Visual Inspection | Monthly | Check for leaks, wear, and proper operation |

| System Flush | Quarterly | Remove debris and contaminants |

| Electrical Check | Biannually | Ensure secure and corrosion-free connections |

| Pressure Test | Annually | Verify that pressure levels are within limits |

For more detailed information on how a 2-way control valve works, visit our guide on how does a 2 way control valve work. Additionally, understanding the differences between a 2 way and 3 way solenoid valve can help you make more informed decisions in your farming operations.