Motorized Solenoid Valves: Features, Applications, and Benefits

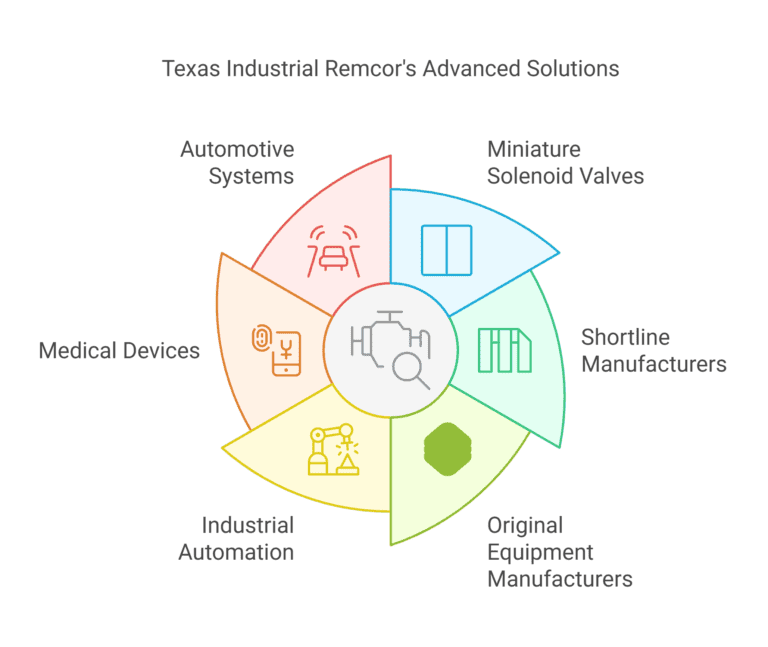

Motorized solenoid valves play a crucial role in fluid control systems, offering a balance of automation, precision, and efficiency. At Texas Industrial Remcor, Inc., we specialize in high-quality solenoid valves and motorized ball valves designed for various industrial applications. Understanding the differences, applications, and advantages of these valves is essential for making informed purchasing decisions.

Understanding Electric Solenoid Valves

Electric solenoid valves are electromechanical devices that regulate fluid flow by using an electric current to control a plunger or diaphragm. When energized, the solenoid generates a magnetic field that lifts the plunger, allowing fluid to pass through.

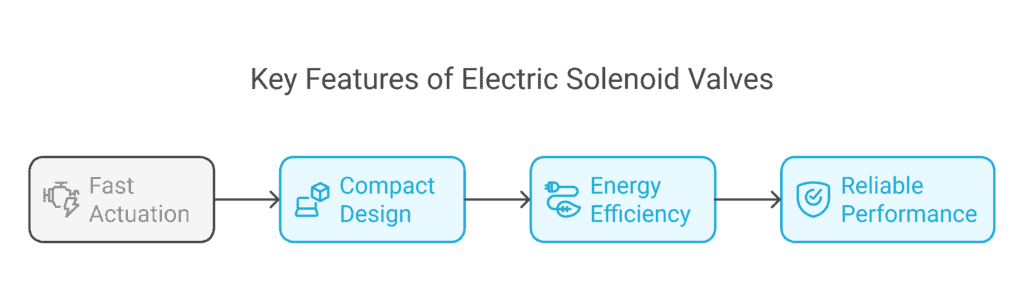

Key Features of Electric Solenoid Valves:

- Fast Actuation – Ideal for applications requiring rapid on/off control.

- Compact Design – Suitable for systems with space constraints.

- Energy-Efficient – Only consumes power during actuation.

- Reliable Performance – Minimal moving parts reduce maintenance needs.

Applications:

- Irrigation Systems: Used in automated watering setups.

- Water Treatment Plants: Controls fluid flow in purification processes.

- HVAC Systems: Manages refrigerant and water flow in heating and cooling systems.

- Industrial Automation: Regulates air, gas, and liquid flow in automated machinery.

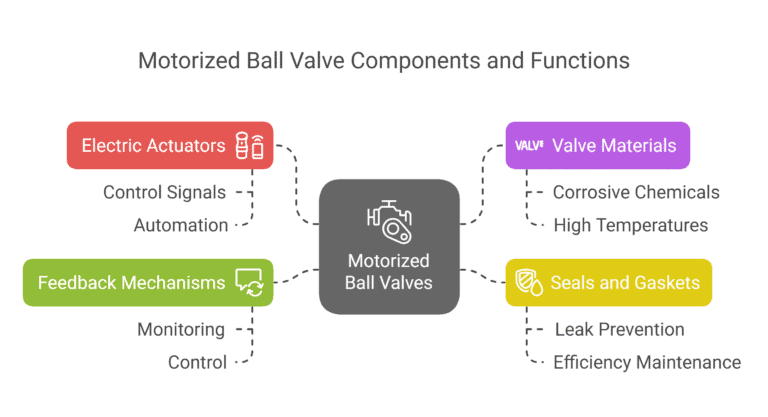

Understanding Motorized Ball Valves

Motorized ball valves, on the other hand, use an electric motor to rotate a ball with a hole, controlling fluid flow with precision. Unlike solenoid valves, these can modulate flow instead of just switching between open and closed states.

Key Features of Motorized Ball Valves:

- Precise Flow Control – Enables throttling of flow rather than just on/off operation.

- Durability – Built for high-pressure and industrial applications.

- Automated Operation – Works seamlessly with control systems.

- Low Power Consumption – Requires power only during movement, reducing energy costs.

Applications:

- HVAC Systems: Regulates water and air distribution.

- Industrial Processes: Manages flow rates in chemical and pharmaceutical production.

- Water Distribution Systems: Ensures efficient flow in treatment facilities.

- Agricultural Irrigation: Provides accurate water control for large-scale farming.

Key Differences Between Solenoid Valves and Motorized Ball Valves

| Feature | Electric Solenoid Valve | Motorized Ball Valve |

|---|---|---|

| Functionality | Rapid on/off control | Gradual, precise flow control |

| Response Time | Fast | Slower but smoother |

| Durability | Moderate, suited for frequent cycling | High, built for long-term use |

| Power Consumption | Requires continuous power for open state | Uses power only during actuation |

| Cost | Lower upfront cost | Higher but more efficient for long-term use |

Advantages of Using Texas Industrial Remcor, Inc. Solenoid and Motorized Ball Valves

At Texas Industrial Remcor, Inc., we offer industry-leading solenoid valves and motorized ball valves designed for industrial efficiency and reliability. Here’s why our products stand out:

- High-Quality Materials – Manufactured using robust materials to withstand harsh conditions.

- Custom Solutions – We provide tailored valve solutions to fit unique industrial needs.

- Energy Efficiency – Designed for minimal power consumption, reducing operational costs.

- Wide Range of Applications – Suitable for industries like agriculture, manufacturing, HVAC, and water treatment.

For more details on our electric solenoid valves, visit our Solenoid Valves Page. If you’re looking for durable, high-performance motorized ball valves, check out our Motorized Valve Selection.

Choosing the Right Valve for Your Needs

When deciding between an electric solenoid valve and a motorized ball valve, consider the following factors:

- Application Requirements: Do you need fast on/off control or gradual flow regulation?

- Fluid Type & Pressure: What type of fluid is being controlled, and at what pressure levels?

- Budget Constraints: Are you looking for a cost-effective solution or a long-term investment?

- Maintenance Considerations: How frequently will the valve be cycled, and what are the maintenance needs?

Maintenance and Troubleshooting Tips

For Electric Solenoid Valves:

- Regularly inspect the solenoid coil for wear or overheating.

- Ensure that the valve is free from debris or clogging.

- Check for leaks and replace worn-out seals promptly.

For Motorized Ball Valves:

- Periodically lubricate the moving parts for smooth operation.

- Verify that the motor is functioning correctly.

- Test the valve’s movement to confirm proper positioning and alignment.

Final Thoughts

Both electric solenoid valves and motorized ball valves play vital roles in fluid control applications. While solenoid valves offer fast, simple operation, motorized ball valves provide greater precision and durability for high-flow applications.

For premium-quality solenoid valves and motorized ball valves, explore our full range at Texas Industrial Remcor, Inc. Visit our website to learn more about our cutting-edge fluid control solutions and how they can optimize your system’s efficiency.