How does a solenoid valve go bad?

Understanding Solenoid Valves

Basics of Solenoid Valves

A solenoid valve is an electromechanical device that controls the flow of liquids or gases in various applications, including agriculture and crop spraying. At its core, a solenoid consists of a coil that generates a magnetic field when electrical current passes through it. This magnetic field is crucial in converting electrical energy into mechanical motion.

Solenoid valves are used in many industries to automate the flow control process. In crop spraying, these valves play a vital role in ensuring precise application of chemicals, reducing waste, and improving efficiency.

| Component | Function |

|---|---|

| Coil | Generates magnetic field |

| Plunger | Moves to open/close valve |

| Spring | Returns plunger to original position |

| Body | Contains the fluid or gas |

For more information on solenoids, you can explore our detailed guide on solenoid valves.

Types of Solenoid Valves

Understanding the different types of solenoid valves helps in selecting the right one for your specific needs. Each type has its own mechanism and application.

Direct-Acting Solenoid Valves

Direct-acting solenoid valves do not rely on external pressure or additional actuators. The movement of the plunger is solely triggered by the electromagnetic field when the solenoid is energized. These valves are straightforward and reliable, making them ideal for low-flow applications where rapid response is needed.

| Type | Best For |

|---|---|

| Direct-Acting | Low-flow, quick response |

Pilot-Operated Solenoid Valves

Pilot-operated solenoid valves are designed to handle higher flow rates. They use the system’s fluid pressure to assist in opening and closing the valve. The solenoid generates enough force to control the pilot orifice, which in turn controls the main valve orifice. This design is efficient for applications requiring higher flow rates and pressures.

| Type | Best For |

|---|---|

| Pilot-Operated | High-flow, high-pressure |

Three-Way Solenoid Valves

Three-way solenoid valves offer advanced flow control capabilities. They can mix fluids from two different sources or divert fluid between a common inlet and two different outlets. This versatility makes them suitable for complex applications in agriculture, such as controlling the distribution of various crop protection chemicals.

| Type | Best For |

|---|---|

| Three-Way | Mixing, diverting fluids |

For more detailed insights on selecting the right solenoid valve for your crop spraying needs, you can refer to our extensive resources on what triggers a solenoid valve.

By understanding the basics and types of solenoid valves, you can make informed decisions to enhance your crop spraying efficiency and effectiveness.

Working Mechanism of Solenoid Valves

Understanding how solenoid valves operate is crucial for optimizing your crop spraying system. In this section, we will explore the mechanics behind two common types of solenoid valves: direct-acting and pilot-operated.

Direct-Acting Solenoid Valves

Direct-acting solenoid valves are straightforward in their operation. They do not need external pressure or additional actuators to function. The movement of the plunger is triggered solely by the electromagnetic field generated when the solenoid is energized.

These valves have a seat seal attached to the solenoid core. When de-energized, the seat orifice is closed. Upon energizing, the valve opens. In two-way valves, the core spring, assisted by fluid pressure, holds the valve seal on the valve seat to shut off the flow when de-energized.

| Feature | Direct-Acting Solenoid Valve |

|---|---|

| External Pressure Needed | No |

| Operation | Electromagnetic field |

| Ports | One inlet, one outlet |

| Common Use | Shut-off valves |

For more on what triggers a solenoid valve, visit our dedicated article here.

Pilot-Operated Solenoid Valves

Pilot-operated solenoid valves, on the other hand, rely on the assistance of the service fluid’s pressure for their operation. The solenoids generate enough force to control the opening and closing of pilot orifices, affecting the diaphragms and main valve orifices (Types of Solenoids).

These valves are typically used for switching higher pressures in conjunction with larger orifice sizes. They are fitted with either a 2- or 3-way pilot solenoid valve, where a diaphragm or a piston provides the seal for the main valve seat (Solenoid).

| Feature | Pilot-Operated Solenoid Valve |

|---|---|

| External Pressure Needed | Yes |

| Operation | Service fluid pressure and solenoid force |

| Ports | Multiple configurations |

| Common Use | High-pressure applications with larger orifices |

Understanding how these valves work can help you make informed decisions about maintaining and troubleshooting your equipment. For more insights, check out our section on solenoid valves.

Applications of Solenoid Valves

Solenoid valves play a critical role in various agricultural applications, particularly in crop spraying systems. Understanding their applications can help you make informed decisions about your equipment.

Three-Way Solenoid Valves

Three-way solenoid valves are especially versatile and offer advanced flow control capabilities beyond simple on/off fluid control. These valves are ideal for mixing fluids from two different sources or diverting fluids between a common inlet and two destinations (Control Solenoid Valve).

- Three Port Connections: These valves have three port connections and two valve seats. One valve seal always remains open while the other is closed in the de-energized mode. When the coil is energized, the mode reverses.

- Fluid Mixing and Diverting: This feature allows for various operations depending on how the fluid medium is connected to the working ports. It makes three-way solenoid valves highly adaptable for tasks such as mixing fertilizers or pesticides with water or diverting spray fluids to different sections of your field (Select Solenoid).

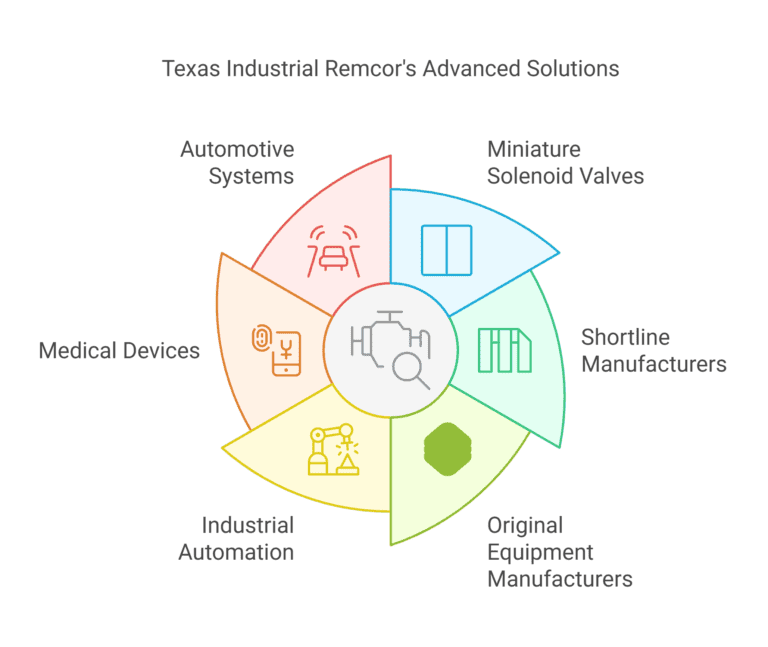

Industrial Use Cases

In agricultural settings, solenoid valves are used in a variety of industrial applications to improve efficiency and control.

- Crop Spraying Systems: Solenoid valves ensure precise control of fluid flow, which is crucial for effective crop spraying. By using solenoid valves, you can automate the spraying process, ensuring even distribution of pesticides, herbicides, or fertilizers. This can lead to better crop yields and reduced chemical usage.

- Irrigation Systems: Solenoid valves are also used in irrigation systems to control water flow. They can be integrated with sensors and timers to automate irrigation based on soil moisture levels, reducing water wastage and ensuring optimal hydration for crops.

- Fertilizer Injection Systems: These valves can be used to inject fertilizers into irrigation systems, allowing for precise control over the amount and timing of fertilizer application. This helps in promoting healthy crop growth and reducing the risk of over-fertilization.

| Application Area | Benefit |

|---|---|

| Crop Spraying | Precise control of fluid flow, even distribution of chemicals |

| Irrigation | Automated water flow control, reduced water wastage |

| Fertilizer Injection | Precise fertilizer application, promotes healthy crop growth |

For more insights into solenoid valves and their diverse applications, check out our comprehensive guide on solenoid valves. Understanding what triggers a solenoid valve? can also help you troubleshoot and maintain your equipment effectively.

Maintenance and Troubleshooting

Importance of Regular Inspection

For middle-aged farmers looking to improve their crop spraying, understanding the importance of routine inspection of solenoid valves is crucial. Regular maintenance can help prevent failures that might lead to significant issues such as loss of control over fluid flow, leakage, system malfunctions, safety risks, production delays, and financial losses. Regularly inspecting your solenoid valves and addressing any signs of wear or damage can ensure optimal performance in your agricultural operations.

Key Inspection Points:

- Visual Inspection: Look for signs of wear, rust, or damage on the valve and its components.

- Functional Testing: Ensure the valve opens and closes correctly. Listen for any unusual sounds that might indicate a problem.

- Electrical Check: Verify that the solenoid coil is receiving the correct voltage and current. A multimeter can be used for this purpose.

Dealing with Solenoid Valve Failures

When solenoid valves fail, it can disrupt your crop spraying operations significantly. Understanding what triggers a solenoid valve? to go bad is essential for effective troubleshooting. Common causes of failure include electrical issues, mechanical wear, and contamination. Addressing these problems promptly can minimize downtime and maintain the efficiency of your agricultural processes.

Common Causes of Solenoid Valve Failures:

- Electrical Issues: Faulty wiring or a burned-out coil can cause the valve to malfunction.

- Mechanical Wear: Over time, the moving parts within the valve can wear out, leading to failure.

- Contamination: Dirt or debris can obstruct the valve, preventing it from operating correctly.

Troubleshooting Steps:

- Check Power Supply: Ensure the valve is receiving the correct voltage. Inspect the wiring for any signs of damage.

- Inspect the Coil: Use a multimeter to check the resistance of the coil. A reading outside the manufacturer’s specifications indicates a problem.

- Clean the Valve: Disassemble the valve and clean all components thoroughly to remove any debris.

- Replace Worn Parts: If any parts are worn or damaged, replace them with new ones to restore functionality.

| Symptom | Possible Cause | Solution |

|---|---|---|

| Valve not opening | Faulty wiring, burned-out coil | Check and repair wiring, replace coil |

| Valve not closing | Contamination, mechanical wear | Clean the valve, replace worn parts |

| Unusual noises | Electrical issues, obstruction | Inspect and resolve electrical issues, clean valve |

Regular inspection and prompt troubleshooting of your solenoid valves can help maintain the efficiency of your crop spraying operations. For more detailed information on maintaining and troubleshooting solenoid valves, visit our articles on what triggers a solenoid valve? and solenoid valves.