How do I know what solenoid valve I need?

Understanding Solenoid Valves

Basics of Solenoid Valves

A solenoid valve is an electromechanically operated valve used to control the flow of liquids or gases. In the context of agriculture, particularly crop spraying, a 2-way solenoid valve is commonly used. This type of valve has two ports: an inlet and an outlet. It allows or blocks flow through the system based on electrical signals. Ensuring the correct flow direction through the valve is crucial for its proper operation.

| Feature | Description |

|---|---|

| Ports | Inlet and Outlet |

| Operation | Allows or blocks flow |

| Application | Crop Spraying |

| Importance | Correct flow direction is essential |

Components of a Solenoid Valve

Understanding the components of a solenoid valve can help you choose the right one and maintain it properly. Here are the key parts:

- Coil: The coil is the core of a solenoid valve. Its design, including the number of turns, wire gauge, and insulation type, influences the valve’s performance by affecting its resistance, inductance, and current-carrying capacity.

- Plunger: Typically made of iron or steel, the plunger affects the valve’s performance by influencing factors such as travel distance, magnetic force, and response time (Sprayer Valves).

- Valve Seat and Seal: These components ensure proper operation by providing a tight seal and compatibility with the fluid or gas being controlled. Damage to these parts can cause leaks, reduced flow, or complete valve failure.

- Valve Body: This houses all the components and must be designed to withstand the pressure and temperature of the fluid or gas being controlled. It also affects flow characteristics such as pressure drop, flow rate, and flow direction (Sprayer Valves).

| Component | Material | Function |

|---|---|---|

| Coil | Copper or Aluminum | Influences resistance, inductance, and current capacity |

| Plunger | Iron or Steel | Affects travel distance, magnetic force, and response time |

| Valve Seat/Seal | Various Polymers | Ensures tight seal, prevents leaks |

| Valve Body | Metal or Plastic | Withstands pressure and temperature |

For more detailed explanations about how these components work together, visit our articles on what is the difference between a 2 way and 3 way solenoid valve? and how does a 2 way control valve work?.

Functionality of 2-Way Solenoid Valves

When it comes to crop spraying and other agricultural applications, understanding the functionality of a 2 way solenoid valve is essential for efficient operation. In this section, you’ll learn about the operation of these valves and the importance of flow direction.

Operation of a 2-Way Solenoid Valve

A 2-way solenoid valve has two ports: an inlet and an outlet. The term “2-way” refers to its two states: open and closed. This valve is designed to control the flow of media (gas, liquid, or air) through its ports by opening or closing in response to an electrical signal.

In a normally closed 2-way solenoid valve, the valve stays closed when no electrical signal is present. The inlet, known as the cavity port, and the outlet, known as the body orifice port, remain blocked. When the valve is energized, the plunger opens, allowing the media to flow through the cavity port and out the body orifice port. When the power is turned off, the orifice closes, stopping the flow.

| State | Port Status |

|---|---|

| Normally Closed | Inlet and outlet ports are blocked when no electrical signal is present |

| Energized | Plunger opens, allowing media flow from inlet to outlet |

| De-energized | Orifice closes, stopping the flow |

Importance of Flow Direction

Ensuring the correct flow direction through a 2 way solenoid valve is crucial for its proper operation. The valve’s design relies on media entering through the inlet and exiting through the outlet. Incorrect flow direction can lead to malfunction or inefficient operation.

Flow direction is typically marked on the valve body. Always follow these markings during installation to maintain proper functionality. Correct flow direction ensures that the valve opens and closes as intended, allowing smooth and controlled flow of fluids or gases.

Understanding the operation and flow direction of a 2-way solenoid valve can significantly improve the efficiency of your agricultural applications, including crop spraying. For more detailed insights, visit our articles on how does a 2 way control valve work and what is the difference between a 2 way and 3 way solenoid valve.

Maintenance and Troubleshooting

Maintaining your 2-way solenoid valve is crucial for ensuring optimal performance and longevity. Understanding common issues and knowing proper maintenance techniques can help you avoid unnecessary downtime and costly repairs.

Common Issues with Solenoid Valves

Several issues can arise with 2-way solenoid valves, affecting their functionality and efficiency. Here are some common problems:

| Issue | Description | Solution |

|---|---|---|

| Coil Failure | The coil no longer generates a magnetic field. | Check power supply and replace the coil if necessary. |

| Blockages | Debris obstructs the valve, preventing proper operation. | Clean the valve and remove any obstructions. |

| Leaks | Wear and tear on the valve seal can cause leaks. | Replace the valve seal and inspect for damage. |

| Electrical Faults | Poor connections or faulty wiring affect valve operation. | Check and repair wiring connections. |

For more detailed troubleshooting, visit our article on how does a 2 way control valve work.

Maintenance Tips for Solenoid Valves

Regular maintenance of your solenoid valve is essential to ensure it operates efficiently and has a long lifespan. Here are some key maintenance tips:

- Regular Inspection: Inspect the valve every 6 to 12 months, depending on the application and manufacturer’s recommendations.

- Cleaning: Ensure that the valve parts are clean and free of debris. Excessive noise or sluggish operation indicates the valve needs cleaning.

- Seal Replacement: Wear and tear on the valve seal can lead to leaks. Regularly check and replace seals as needed.

- Component Replacement: Replace any worn-out components and ensure proper lubrication to extend the life of the valve components.

- Check Electrical Connections: Inspect for any electrical faults, ensuring all connections are secure and functioning correctly.

By following these maintenance tips and addressing common issues promptly, you can ensure that your 2-way solenoid valve continues to function effectively. For more information on solenoid valves, including their applications and benefits, check out our related articles on what is the difference between a 2 way and 3 way solenoid valve? and 2 way solenoid valve.

Applications and Benefits

Versatility of Solenoid Valves

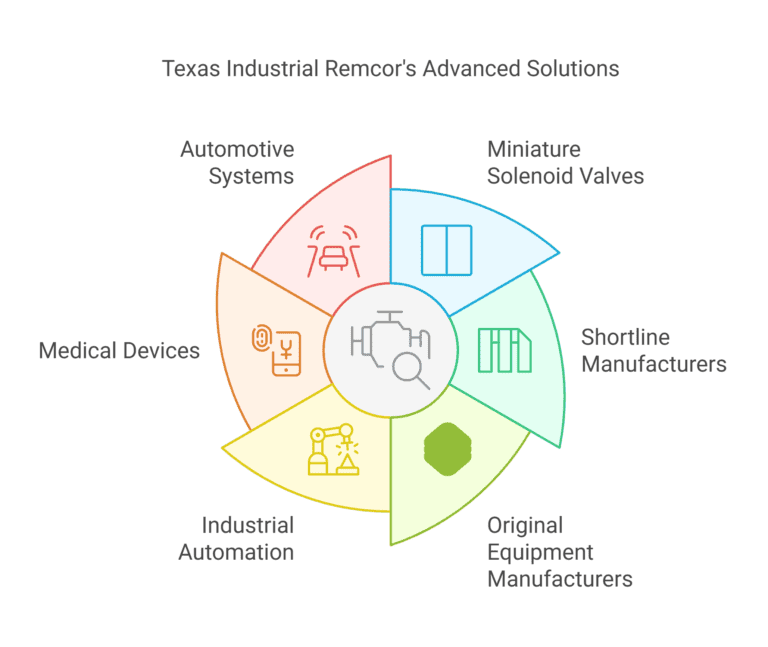

Solenoid valves, particularly the 2 way solenoid valve, are highly versatile and can be used across a wide range of applications. They are commonly utilized in industries such as water treatment, automotive, food processing, and many other industrial sectors. The ability to control these valves remotely and automatically makes them valuable in various automated systems.

In agriculture, 2 way solenoid valves are often employed in crop spraying systems. These valves control the flow of liquids, ensuring precise and efficient distribution of pesticides and fertilizers across your fields. Another common use is in automated irrigation systems, where solenoid valves regulate the flow of water through different zones, watering lawns, gardens, or outdoor plants efficiently.

| Application | Industry |

|---|---|

| Crop Spraying | Agriculture |

| Water Treatment | Industrial |

| Automotive Systems | Automotive |

| Food Processing | Food Industry |

| Irrigation Systems | Agriculture |

Benefits of Using Solenoid Valves

The use of 2 way solenoid valves offers numerous benefits, enhancing the functionality and efficiency of your systems. Key advantages include:

- Safety Features: Solenoid valves can be designed with fail-safe mechanisms that automatically close the valve in case of power failure, preventing potential hazards.

- Efficiency: Their near-instantaneous switching between fully open and fully closed states makes them ideal for precise on/off control, conserving energy and resources.

- Versatility: These valves are suitable for controlling various fluids, including water, air, oil, and chemicals, making them adaptable to different applications.

- Remote Control: Being electrically controlled, solenoid valves can be easily integrated into automated systems, allowing for remote operation and monitoring.

- Proportional Control: Some solenoid valves offer proportional control, modulating flow rates for more nuanced and precise fluid management.

For more information on how these valves operate, you can explore our article on how does a 2 way control valve work.

By leveraging the versatility and benefits of 2 way solenoid valves, you can optimize your agricultural processes, improve efficiency, and ensure the safety of your operations. For further understanding of the differences between solenoid valves, visit our detailed guide on what is the difference between a 2 way and 3 way solenoid valve?.