The Hidden Mechanics of Solenoid Valves: Why Reliability Matters in Modern Industries

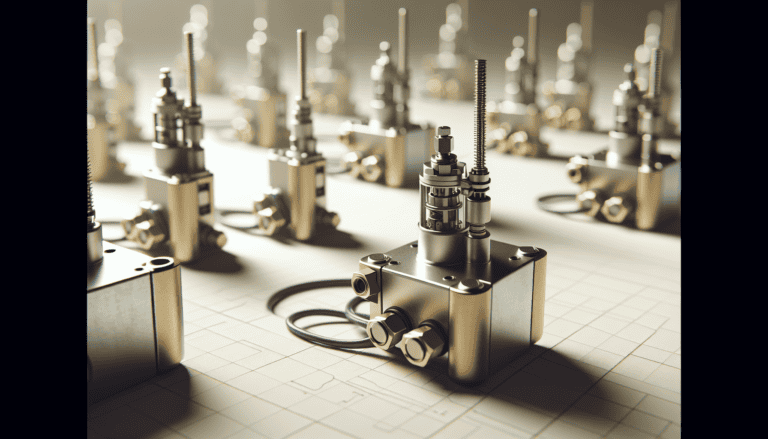

When the stakes are high—whether you’re managing a precision agriculture operation, automating industrial machinery, or maintaining turf on a championship golf course—the reliability of your equipment isn’t just a luxury. It’s a necessity. At the heart of these systems lie solenoid valves, the unsung heroes controlling fluid and gas flow with surgical precision. But what happens when these components fail? And how do industry leaders like Texas Industrial Remcor engineer valves that outlast the competition? Let’s break it down.

How Solenoid Valves Work: The Science of Precision

Solenoid valves are electromechanical devices that act as gatekeepers for fluids and gases. When energized, an electromagnetic coil (solenoid) generates a magnetic field, pulling a plunger to open or close the valve. This simple yet elegant mechanism allows for rapid, automated control—critical in applications like crop spraying or hydraulic systems.

Texas Industrial Remcor’s valves take this basic principle further. Built with corrosion-resistant materials like stainless steel and brass, their designs withstand harsh environments, from chemical-laden agricultural fields to high-pressure industrial setups. Their engineering process focuses on minimizing wear, ensuring consistent performance even after millions of cycles.

Normally Closed vs. Normally Open: Which Configuration Wins?

One of the first decisions when selecting a solenoid valve is its default state. Normally closed (NC) valves shut off flow when de-energized, ideal for safety-critical systems like emergency shutoffs. Normally open (NO) valves allow flow until power is applied, useful in ventilation or cooling systems.

Texas Industrial Remcor offers both configurations, but their NC valves dominate in agriculture. Why? Farmers can’t afford leaks. A single malfunction during chemical application could waste thousands of dollars or damage crops. By defaulting to “closed,” these valves add a layer of fail-safe protection.

Direction Matters: Are Solenoid Valves Directional?

Not all valves are created equal when it comes to flow direction. Some are bidirectional, while others require specific inlet/outlet orientations. Texas Industrial Remcor’s designs prioritize versatility—many of their 2-way and 3-way valves handle bidirectional flow, simplifying installation in complex systems like industrial automation networks.

Why Do Solenoid Valves Fail? (And How to Prevent It)

Even the best valves can falter under extreme conditions. Common failure points include:

| Failure Cause | Symptoms | TIR’s Solution |

|---|---|---|

| Coil Burnout | Valve stops responding | High-temp resistant coils with UV protection |

| Debris Contamination | Erratic operation | Stainless steel filters & self-cleaning ports |

| Seal Degradation | Leaks | Chemical-resistant elastomers (e.g., Viton®) |

| Voltage Fluctuations | Intermittent function | Low-power coils (0.5W) with surge protection |

Texas Industrial Remcor tackles these issues head-on. Their valves feature debris-resistant designs and coils rated for extreme temperatures, a must for agricultural sprayers exposed to sun, dust, and corrosive chemicals.

The Texas Industrial Remcor Edge: Built for the Long Haul

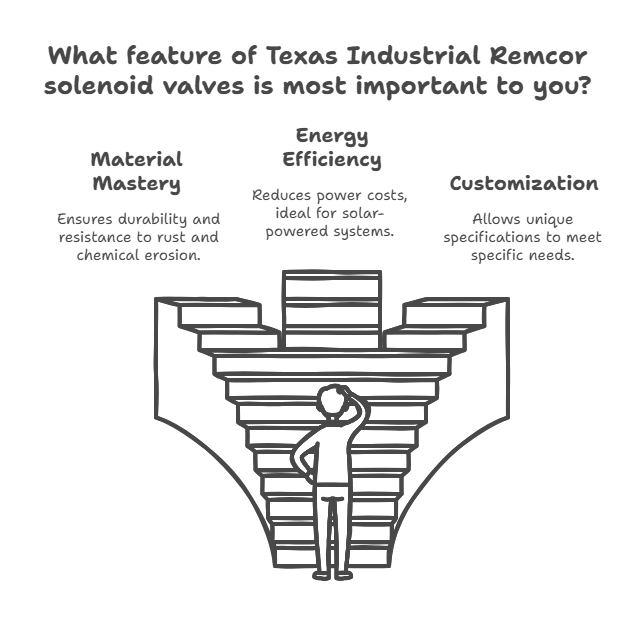

What separates a good solenoid valve from a great one? It’s not just specs—it’s how those specs translate to real-world performance.

- Material Mastery: Brass and stainless steel bodies resist rust and chemical erosion.

- Energy Efficiency: Some models draw as little as 0.5W, slashing power costs in solar-powered systems.

- Customization: Need a valve with a unique port size or voltage? Their team can engineer it.

- Speed: With most orders shipped in 48 hours, downtime isn’t an option.

Final Thoughts: Why Settle for Less?

In industries where downtime equals lost revenue, the choice of solenoid valves isn’t just technical—it’s strategic. Texas Industrial Remcor’s USA-made valves blend ruggedness with precision, backed by a 25-year reputation for reliability. Whether you’re retrofitting a fleet of street sweepers or automating a bottling plant, their solutions are engineered to endure.

Ready to upgrade your system’s reliability? Explore Texas Industrial Remcor’s full range of high-performance solenoid valves or connect with their technical support team for a custom solution.

Innovation isn’t about reinventing the wheel—it’s about making it spin flawlessly, every single time.