Top Benefits of TIR E-Chip™ Smart Technology for Farmers

Texas Industrial Remcor, Inc. (TIR) offers advanced solenoid valves equipped with their innovative TIR E-Chip™ smart technology, which brings several benefits to farmers. One key advantage is the significant reduction in power consumption, helping extend battery life and lower operating costs. The TIR E-Chip™ also improves valve reliability by stabilizing electrical input and reducing wear, resulting in less maintenance during important spraying periods. Farmers gain precise fluid control for fertilizers and pesticides that reduces waste and environmental impact. Plus, the technology supports integration with smart farming systems for real-time monitoring and optimized operation under different conditions. Overall, TIR’s solutions promote efficient, sustainable farming practices.

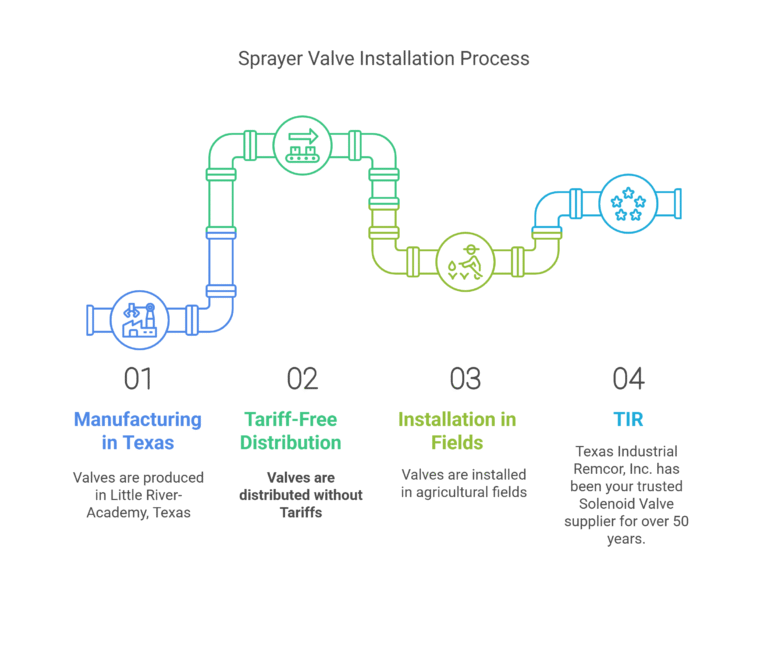

Overview of Texas Industrial Remcor, Inc. and Our Product Range

Texas Industrial Remcor, Inc. (TIR) is a well-established manufacturer specializing in solenoid valves and valve systems designed for fluid control across a variety of industries. Their expertise covers applications in agriculture, street cleaning, turf spraying, and other commercial fluid handling needs. TIR’s products are built to withstand tough conditions, ensuring durability and reliable operation even in demanding environments. At the core of their product line are solenoid valves that use electromagnetic coils to precisely manage fluid flow, providing accurate and efficient control. Beyond mechanical design, TIR integrates advanced electronics to boost valve performance, supporting automation and smart control in fluid delivery. They offer a broad selection of valve sizes and configurations tailored to meet specific fluid control requirements, including valves optimized for agricultural spraying equipment that enable precise and consistent chemical application. With a focus on low maintenance design, TIR valves help reduce downtime and operational costs, making them a practical choice for farmers and other users. Their solutions not only improve resource management but also enhance overall operational efficiency across the industries they serve.

How TIR Solenoid Valves Work in Fluid Control

TIR solenoid valves use an electric coil to create a magnetic field that moves a valve component, allowing the valve to open or close and control fluid flow precisely. When an electrical signal activates the coil, the magnetic force shifts the valve parts to start, stop, or redirect liquids like water, chemicals, or fertilizers. This quick response to electrical input supports exact timing in fluid delivery, which is essential for efficient spraying systems. Designed with compactness in mind, these valves fit easily into automated agricultural machinery, helping farmers manage fluids without leaks thanks to strong sealing components. They handle varying pressures and flow rates reliably, maintaining fluid integrity throughout operation. Remote control capability is another advantage, enabling farmers to adjust fluid flow from a distance and integrate valves into modern precision farming setups. By accurately controlling the volume of liquids applied, TIR solenoid valves help reduce waste and improve resource use. Their straightforward installation and compatibility with existing systems make them practical solutions for upgrading fluid control in farming operations.

What Makes TIR E-Chip™ Smart Technology Unique

The TIR E-Chip™ stands out because it is an embedded electronic control module built right into solenoid valves, allowing precise regulation of electrical input to the valve coil. This smart control reduces power consumption by managing voltage carefully, which not only lowers energy costs but also prevents damage caused by voltage spikes and heat buildup. With less electrical stress, the valves last longer and require less maintenance. The technology also speeds up valve actuation, offering quicker and more reliable fluid control essential for timely spraying tasks. Beyond power and speed, the TIR E-Chip™ supports data communication, enabling real-time monitoring of valve status, which helps farmers catch issues early and optimize their operations. Its rugged design means it can handle tough field conditions without compromising performance. Furthermore, the TIR E-Chip™ integrates smoothly with modern farming equipment and data systems, supporting smart agriculture practices. This combination of energy efficiency, durability, responsiveness, and connectivity makes TIR E-Chip™ a unique and valuable tool for farmers aiming to improve productivity while embracing sustainable methods.

1. Reduction in Power Usage with TIR E-Chip™

TIR E-Chip™ valves use up to 66% less electrical power than traditional solenoid valves, making a noticeable difference in energy consumption on the farm. This lower power demand extends battery life in portable and vehicle-mounted spraying equipment, allowing farmers to work longer without the need for frequent recharging or refueling. Because the valves draw less current, they generate less heat, which not only helps the valves last longer but also reduces the risk of overheating in the system. The reduced electrical load means smaller, lighter batteries or power supplies can be used, which cuts down on equipment weight and overall cost. This efficiency also supports quieter valve operation by minimizing electrical noise. Additionally, the technology performs well even under low voltage conditions, preventing overloads on complex agricultural systems. By lowering fuel and energy consumption, the E-Chip™ helps farmers save on operating expenses and supports sustainability goals by reducing their carbon footprint and environmental impact.

- TIR E-Chip™ valves use up to 66% less electrical power compared to traditional solenoid valves.

- Lower power consumption extends battery life in portable and vehicle-mounted spraying equipment.

- Reduced power needs allow for smaller power supplies or batteries, lowering equipment weight and cost.

- Lower current draw decreases heat generation, contributing to valve and system longevity.

- Energy savings reduce fuel consumption and operating expenses on farms.

- Efficient power use supports longer spraying operations without recharging or refueling.

- The technology enables equipment to operate effectively under low voltage conditions.

- Decreased electrical demand helps prevent overloads in complex agricultural systems.

- Power efficiency contributes to quieter valve operation by reducing electrical noise.

- Overall, reduced energy usage aligns with farm sustainability goals and cost control.

2. Enhanced Reliability and Lower Maintenance Needs

TIR E-Chip™ technology improves valve reliability by stabilizing the voltage and current supplied to the solenoid coil. This reduces electrical wear and prevents damage caused by voltage spikes from unstable power sources. As a result, valve solenoids last longer and require fewer repairs. The technology also lowers heat buildup inside the valve, which decreases stress on both mechanical and electronic parts, helping avoid common failures like valve sticking or malfunction. For farmers, this means less downtime during crucial spraying periods and extended maintenance intervals, which cut labor and parts replacement costs. Additionally, the chip’s ability to simplify diagnostics through data output allows early detection of maintenance needs, supporting timely service before small issues grow. With improved valve durability and consistent performance even in tough environmental conditions, farmers can rely on accurate chemical application without interruption, ensuring efficient and smooth operation throughout the season.

3. Accurate and Fast Fluid Control for Better Crop Care

The TIR E-Chip™ technology enables rapid valve opening and closing, allowing farmers to deliver fluids with precision timing. This quick response ensures that fertilizers, pesticides, and herbicides are applied in exact amounts, which minimizes chemical waste and lowers the risk of harming crops. Faster valve actuation supports advanced spraying techniques like spot spraying and variable rate applications, helping maintain uniform coverage across the field. By controlling fluid flow accurately, farmers can improve pest and weed management outcomes and promote healthier crops. The system also integrates with GPS and sensor data, enabling site-specific spraying that adapts to changing field conditions. This precise control reduces over-application, protecting soil and water quality while cutting input costs. Overall, the enhanced fluid control capabilities of TIR E-Chip™ contribute to better yields and more efficient crop care.

4. Real-Time Data and Smart Farming Integration

TIR E-Chip™ modules provide real-time data by communicating key operational information such as valve status and power consumption. This allows farmers to monitor their spraying equipment remotely, ensuring everything runs smoothly without being on-site constantly. Early alerts for potential faults help prevent costly downtime and protect crops from inadequate spraying. The technology supports seamless integration with farm management software and precision agriculture tools, enabling farmers to make informed decisions based on current weather, soil moisture, and crop growth stages. By using real-time data, farmers can optimize chemical application timing and amounts, improving resource efficiency and reducing waste. Tracking equipment usage metrics also helps plan maintenance and replacements before issues arise. Automated control reduces manual work during spraying, allowing coordinated management of multiple valves and spraying zones. Additionally, the data insights provided by the TIR E-Chip™ support compliance with environmental regulations, making it easier to document and report farm operations responsibly.

| Feature | Benefit | Impact on Farming |

|---|---|---|

| Operational Data Communication | Enables real-time monitoring of valve status and power usage | Helps farmers track equipment performance remotely for timely decisions |

| Early Fault Detection | Sends alerts on potential issues | Prevents costly downtime and crop damage |

| Integration with Farm Management Software | Supports compatibility with precision agriculture tools | Allows data-driven control and optimization of spraying operations |

| Data-Driven Adjustments | Adjusts spraying based on weather, soil moisture, and crop stages | Improves resource efficiency and application accuracy |

| Remote Monitoring and Automation | Reduces manual intervention | Streamlines spraying operations and increases productivity |

| Coordinated Control of Multiple Valves | Manages multiple spraying zones simultaneously | Enhances operational precision and flexibility |

| Compliance Support | Provides data for environmental reporting | Assists adherence to regulations and sustainability goals |

5. Resistance to Harsh Conditions and Temperature

TIR E-Chip™ technology significantly lowers valve operating temperatures by reducing electrical losses, which helps maintain reliable valve performance even in extreme hot or cold environments. The valves and chips are built to endure common field challenges such as dust, moisture, and chemical exposure without compromising functionality. Their robust construction prevents corrosion and mechanical damage from rough handling, while stable electronic components resist failures caused by temperature swings. This ensures consistent valve response despite environmental stresses like vibration and shock, especially important for mobile spraying equipment. The design also preserves sealing integrity against agricultural chemicals and UV exposure, supporting year-round use regardless of weather conditions. As a result, the technology extends equipment service life and cuts down the need for frequent replacements, offering farmers dependable operation through all seasons.

6. Supporting Sustainable and Eco-Friendly Farming Practices

The TIR E-Chip™ Smart Technology promotes sustainable farming by cutting energy use during spraying operations, which lowers the overall carbon footprint. Its precise fluid control reduces chemical runoff, helping to protect nearby soil and water from contamination. By efficiently managing valve operations, it minimizes waste of fertilizers and pesticides, ensuring only the necessary amount is applied. Longer equipment life and fewer replacements mean less material waste and reduced environmental impact. Lower maintenance demands also save resources by cutting down on repairs and spare parts. Integrated smart data supports targeted spraying, conserving inputs while safeguarding ecosystems. This technology helps farmers meet environmental regulations on chemical use and appeals to consumers who prioritize eco-friendly farming. Its energy-efficient valves assist farms aiming to reduce resource consumption and maintain soil health by preventing over-application, aligning well with the growing trend toward responsible agriculture.

Future of Agricultural Spraying with TIR E-Chip™ Technology

TIR E-Chip™ technology lays the groundwork for more automated and connected spraying systems, moving agriculture closer to fully smart operations. By integrating with Internet of Things (IoT) devices, farmers will gain enhanced monitoring and control over spraying, allowing adjustments based on real-time data from fields. Future advancements are likely to bring in deeper data analytics, helping optimize spraying schedules to match crop needs and weather conditions precisely. The technology’s support for variable rate applications means spraying can adapt dynamically to soil and crop variability, improving resource use and crop health. As electric and autonomous farm machinery become more common, TIR E-Chip™ is expected to improve compatibility with these platforms, supporting wireless communication and remote firmware updates for easier maintenance. Continuous innovation will focus on lowering energy consumption and minimizing environmental impact, aligning with stricter regulations and sustainability goals. Collaborations with precision agriculture platforms will further enhance farm management integration, making TIR E-Chip™ a key part of the future of efficient, eco-friendly spraying. Texas Industrial Remcor, Inc. will keep refining valve and chip designs to boost performance and simplify usage, helping farmers meet the demands of modern agriculture with smarter, more reliable technology.

Frequently Asked Questions

1. How does TIR E-Chip™ Smart Technology improve farm machinery efficiency?

TIR E-Chip™ optimizes farm machinery by providing real-time data on usage and performance. This helps farmers schedule maintenance accurately, avoid breakdowns, and improve fuel efficiency, which overall enhances operational efficiency.

2. In what ways can TIR E-Chip™ assist farmers in managing crop health?

The technology collects precise data from sensors and equipment used in the field, allowing farmers to monitor soil conditions, moisture levels, and nutrient distribution. This enables better decision-making for irrigation and fertilization, promoting healthier crops.

3. How does TIR E-Chip™ help in reducing resource wastage on farms?

By delivering accurate information about equipment usage and environmental factors, TIR E-Chip™ allows farmers to apply water, fertilizers, and pesticides more precisely. This targeted approach reduces unnecessary consumption and environmental impact while saving costs.

4. What role does TIR E-Chip™ play in enhancing farm safety and asset security?

TIR E-Chip™ provides tracking and monitoring capabilities for farm equipment, helping farmers detect unauthorized use or theft quickly. It also supports safety by alerting users to potential mechanical issues before they become hazardous.

5. Can TIR E-Chip™ technology integrate with existing farm management systems, and what benefits does this offer?

Yes, TIR E-Chip™ is designed to integrate smoothly with various farm management software. This integration consolidates data to give farmers a comprehensive view of their operations, improving planning, resource allocation, and overall productivity.

TL;DR Texas Industrial Remcor, Inc. offers advanced solenoid valves with TIR E-Chip™ smart technology that helps farmers reduce power use, improve valve reliability, and achieve precise fluid control. This tech supports real-time data integration for smart farming, withstands harsh conditions, and promotes sustainable agriculture by lowering energy consumption and chemical waste. Overall, TIR E-Chip™ enhances farming efficiency and equipment durability, making it a practical choice for modern agricultural spraying systems.