Motorized Ball Valves in Today’s Fluid Control Systems

Table of Contents

- Understanding Motorized Ball Valves

- The Mechanics of Motorized Ball Valves

- Industries Using Motorized Ball Valves

- Benefits of Using Motorized Ball Valves

- Texas Industrial Remcor, Inc. Overview

- Product Range at Texas Industrial Remcor, Inc.

- Frequently Asked Questions

Motorized ball valves are essential in today’s fluid control systems, significantly enhancing efficiency across various applications. These valves utilize electric actuators to automate the opening and closing process, allowing for precise flow regulation of liquids or gases. Their quick response times ensure minimal fluid loss while maintaining safety standards. With zero-leakage seals and low maintenance requirements, they suit industries like food processing, HVAC, and water management. Texas Industrial Remcor, Inc., offers a range of high-quality motorized ball valves tailored to meet diverse customer needs—ensuring that operations run smoothly in agriculture and manufacturing sectors alike.

1. Understanding Motorized Ball Valves

Motorized ball valves are vital components in today’s fluid control systems. They feature an electric actuator that automates their operation, allowing for precise control of fluid flow. These valves are primarily used for on/off control, making them straightforward yet effective in managing various liquids and gases. Their reliability and durability are noteworthy, ensuring long-lasting performance even in demanding environments. Available in a range of sizes and materials, motorized ball valves can be tailored to meet the specific needs of different applications, including those involving corrosive fluids.

One of the key benefits of motorized ball valves is their design, which allows for minimal pressure drop when the valve is fully open. This characteristic optimizes the flow and enhances system efficiency. Furthermore, they can be installed in multiple orientations, offering flexibility in installation. This versatility makes them suitable for both residential and industrial settings, where ease of use and low maintenance are highly valued. Whether in a home heating system or in large-scale manufacturing processes, motorized ball valves play a crucial role in ensuring smooth and efficient fluid control.

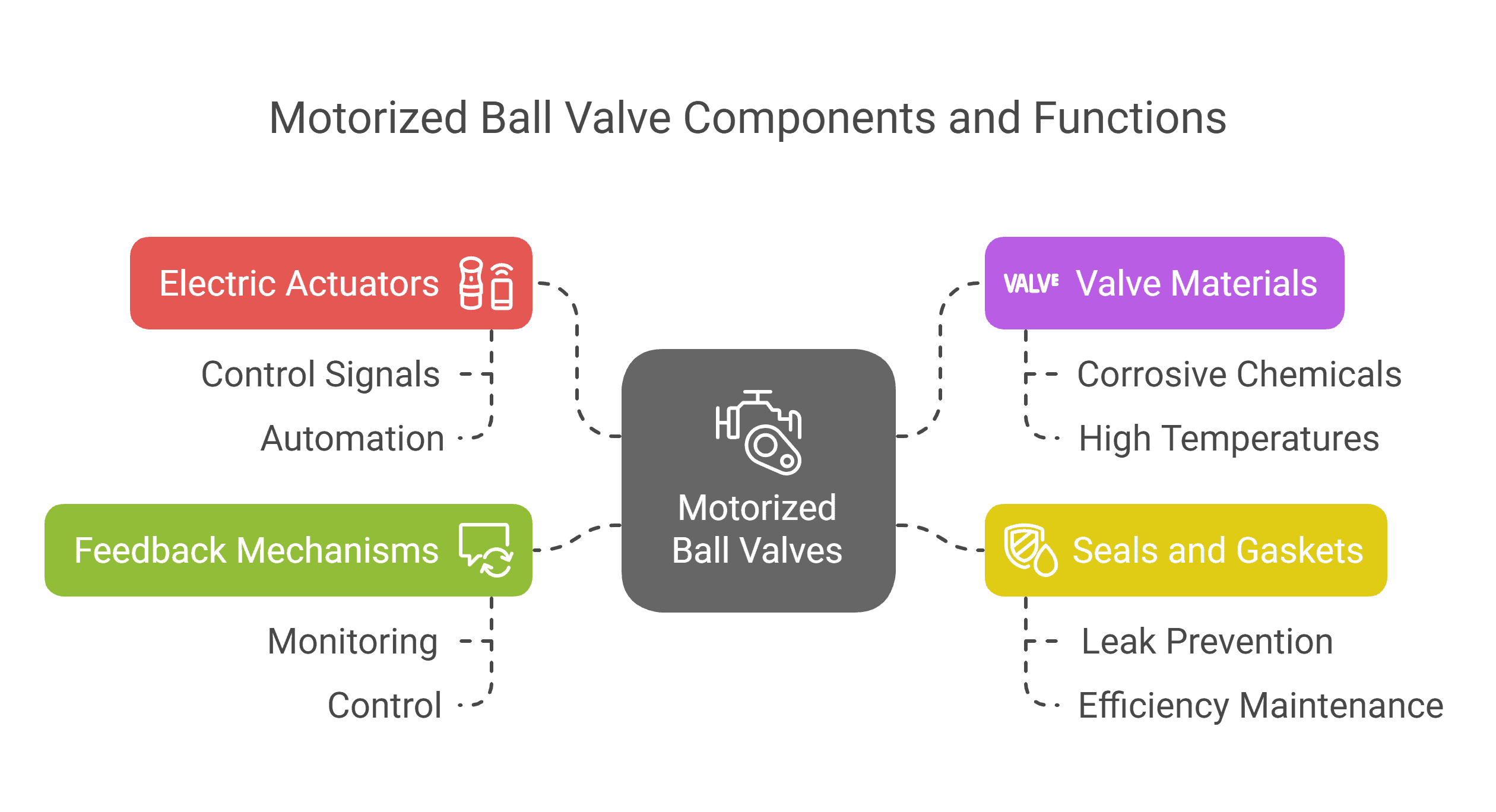

2. The Mechanics of Motorized Ball Valves

Motorized ball valves operate using electric actuators that provide precise control over the valve’s position. These actuators receive signals from control systems, enabling automation of fluid flow management. Typically, ball valves rotate 90 degrees to either open or close, ensuring quick operation when needed. The materials used in constructing these valves play a significant role in their performance across various environments, whether they are dealing with corrosive chemicals or high temperatures. Additionally, seals and gaskets are essential components, as they prevent leaks and maintain the efficiency of the system. Depending on the application requirements, different types of actuators can be selected, allowing for tailored solutions. Integration of motorized ball valves into existing systems is generally straightforward, requiring minimal modifications. Feedback mechanisms in the actuators can provide real-time status updates, which are vital for monitoring and control. The design of these valves allows for easy troubleshooting and replacement of parts, which simplifies maintenance. For optimal performance, regular testing of both the actuator and the valve functions is recommended.

3. Industries Using Motorized Ball Valves

Motorized ball valves are widely used across various industries due to their efficiency and precision in fluid control. In the oil and gas sector, they play a crucial role in managing the flow of hydrocarbons, ensuring safety and efficiency in operations. Water treatment facilities rely on these valves to regulate water supply and drainage, which is vital for maintaining clean water standards. In HVAC systems, motorized ball valves help control heating and cooling flows, contributing to energy efficiency in buildings. The food and beverage industry employs these valves to uphold hygiene and safety standards, particularly in processes requiring strict cleanliness. Chemical processing plants utilize them to handle various substances safely, while pharmaceutical manufacturing depends on precise dosing achieved through motorized ball valves. In power generation, these valves control steam and water flow, which is essential for optimal plant operation. The automotive industry also benefits from their use in fluid management systems, ensuring reliable performance. Additionally, irrigation systems use motorized ball valves for efficient water usage, and commercial buildings implement them for plumbing and drainage systems, highlighting their versatility and importance across diverse applications.

| Industry | Application | Significance |

|---|---|---|

| Oil and Gas | Controlling flow | Crucial for safety and efficiency in extraction and processing. |

| Water Treatment | Managing water supply and drainage | Ensures clean water availability and effective wastewater management. |

| HVAC Systems | Regulating heating and cooling flows | Maintains comfortable indoor environments and energy efficiency. |

| Food and Beverage | Maintaining hygiene and safety standards | Critical for compliance with health regulations. |

| Chemical Processing | Handling various substances | Ensures safety and accuracy in chemical manufacturing. |

| Pharmaceutical Manufacturing | Ensuring precise dosing | Vital for product consistency and regulatory compliance. |

| Power Generation | Controlling steam and water flow | Essential for optimal operation of power plants. |

| Automotive Industries | Fluid management systems | Improves vehicle performance and reliability. |

| Irrigation Systems | Efficient water usage | Enhances agricultural productivity through effective resource management. |

| Commercial Buildings | Plumbing and drainage systems | Supports building operations and infrastructure integrity. |

4. Benefits of Using Motorized Ball Valves

Motorized ball valves provide significant advantages in fluid control systems. They offer precise control over fluid flow, which enhances process efficiency in various applications. With automated operation, these valves reduce the need for manual intervention, effectively saving on labor costs. Their fast shut-off capabilities make them essential for enhancing safety during emergencies, allowing systems to respond quickly to potential hazards. Additionally, the robust design of motorized ball valves contributes to a long service life, minimizing the frequency of replacements.

Maintenance is less demanding compared to manual valves, which means reduced downtime for repairs and adjustments. Their compatibility with modern control systems allows for sophisticated monitoring and management, enabling users to track performance and make informed decisions. These valves can handle high pressures and temperatures, making them versatile for a wide range of applications, from industrial processes to HVAC systems. Moreover, the design of motorized ball valves helps reduce the risk of leaks, contributing to environmental safety and regulatory compliance. Overall, integrating motorized ball valves can lead to significant cost savings in operational processes, enhancing both efficiency and safety.

- They offer precise control over fluid flow, improving process efficiency.

- Automated operation reduces the need for manual intervention, saving labor costs.

- They provide fast shut-off capabilities, enhancing safety in emergencies.

- Motorized ball valves have a long service life due to their robust design.

- They require less maintenance compared to manual valves, reducing downtime.

- The ability to integrate with modern control systems allows for sophisticated monitoring.

- They can handle high pressures and temperatures, expanding their application range.

- Reduced risk of leaks contributes to environmental safety and compliance.

- They are versatile, suitable for various fluids and applications.

- Overall, they can lead to significant cost savings in operational processes.

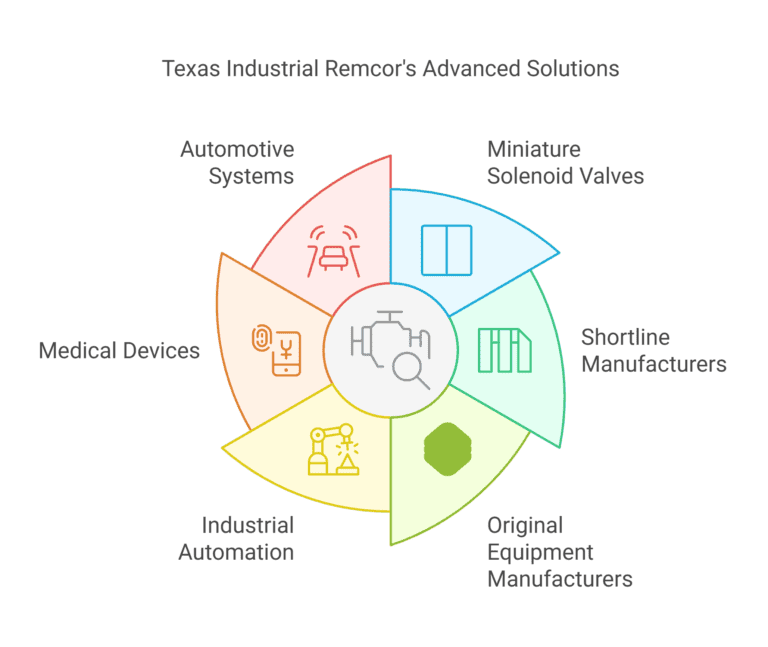

5. Texas Industrial Remcor, Inc. Overview

Texas Industrial Remcor, Inc. was founded with a commitment to providing innovative fluid control solutions. The company specializes in manufacturing high-quality sprayer valves, catering to a diverse range of industries including agriculture, street cleaning, and turf management. Their approach ensures that each sector receives tailored solutions that meet specific operational needs. With a strong focus on research and development, Texas Industrial Remcor continuously improves its product offerings, enhancing performance and reliability. They are dedicated to maintaining high standards of quality control throughout their production processes, utilizing advanced technology to deliver superior products. Additionally, the company prioritizes sustainability and environmentally friendly manufacturing practices. Texas Industrial Remcor has built a strong reputation for reliability and customer satisfaction, supported by extensive customer service and technical assistance. By engaging with industry partners, they stay updated on market trends and evolving needs, positioning themselves as a leader in fluid control solutions.

6. Product Range at Texas Industrial Remcor, Inc.

Texas Industrial Remcor, Inc. offers a comprehensive line of motorized ball valves tailored for various applications. Their product range includes solenoid valves designed for efficient fluid control, ensuring reliability in operations. The valves are constructed from durable materials, making them suitable for harsh environments, which is particularly important for industries like agriculture and manufacturing.

One of the standout features of their offerings is the customizable options available. Clients can specify their unique requirements, allowing for valves that fit perfectly into their existing systems. Additionally, Texas Industrial Remcor develops specialized valves specifically for agricultural and industrial sprayers, addressing the unique needs of these sectors.

Flexibility is another key aspect of their product line, which includes both quick-connect and standard connection options. This versatility makes installation and integration into various setups much simpler. Furthermore, the valves are compatible with different control systems, including PLCs, which enhances their usability in automated environments.

Quality and safety are paramount at Texas Industrial Remcor, with all products meeting industry standards for performance. They regularly update their product line to incorporate the latest technology, ensuring that customers have access to cutting-edge solutions. Despite the high quality of their products, Texas Industrial Remcor maintains competitive pricing, making them an attractive option for businesses looking to enhance their fluid control systems.

Frequently Asked Questions

1. What are motorized ball valves and how do they work?

Motorized ball valves are devices that control the flow of liquids or gases using a ball with a hole in it. The motor operates the ball to open or close the flow path, allowing for precise control in fluid systems.

2. What advantages do motorized ball valves offer in fluid control systems?

Motorized ball valves provide automated control, which enhances efficiency, reduces manual labor, and allows for quick adjustments in fluid flow. They also offer reliable sealing and minimal leakage.

3. How do I know if a motorized ball valve is right for my system?

Choosing a motorized ball valve depends on factors like the type of fluid, temperature, pressure requirements, and the specific control needs of your system. Assessing these factors will help ensure you choose the right valve.

4. Can I use motorized ball valves with different types of fluids?

Yes, motorized ball valves can work with various fluids, including water, chemicals, and gases. However, it is important to select a valve that is compatible with the specific fluid to prevent damage or leaks.

5. How is maintenance performed on motorized ball valves?

Maintenance typically involves regular inspections for leaks, ensuring the motor and electronic components are working smoothly, and cleaning any debris that could affect performance. Following the manufacturer’s guidelines is key to effective maintenance.

TL;DR Motorized ball valves are essential for modern fluid control systems, providing automated flow regulation in various applications from industrial automation to HVAC. They offer key advantages such as rapid response time, low maintenance, and zero-leakage performance. Texas Industrial Remcor, Inc. is a leading supplier of these valves, specializing in sprayer solutions for diverse industries, ensuring efficient and precise fluid management.